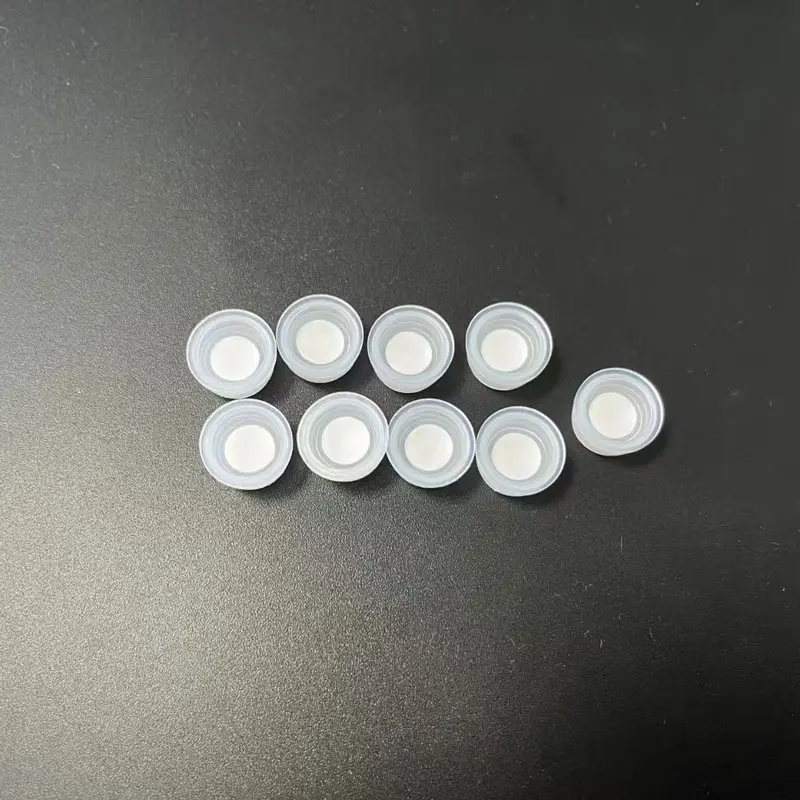

Adhesive Type Vent Membrane

Product Technical Data Sheet

|

PRODUCT NAME : |

Adhesive Type Vent Membrane |

|

PRODUCT MODEL : |

ZZPIP-E90H30+5610_8x4 |

|

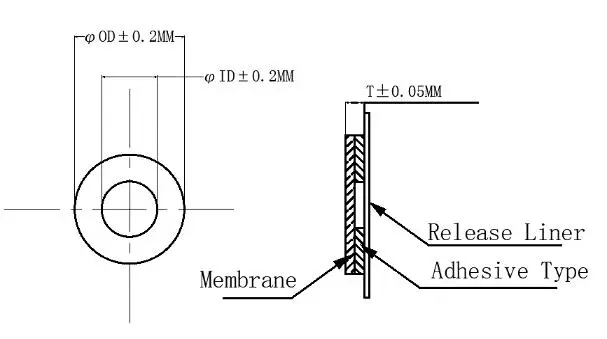

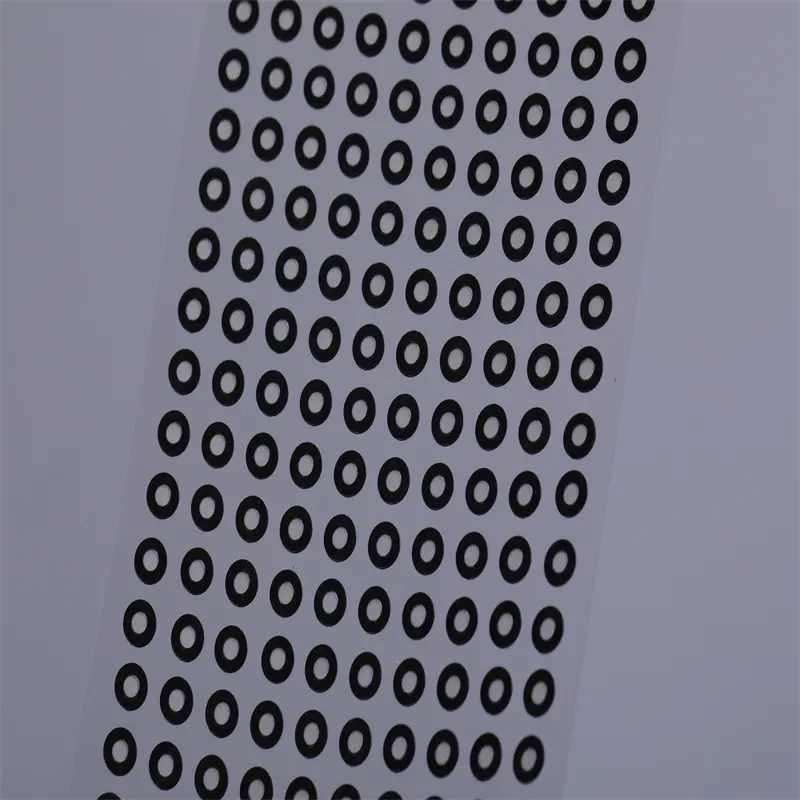

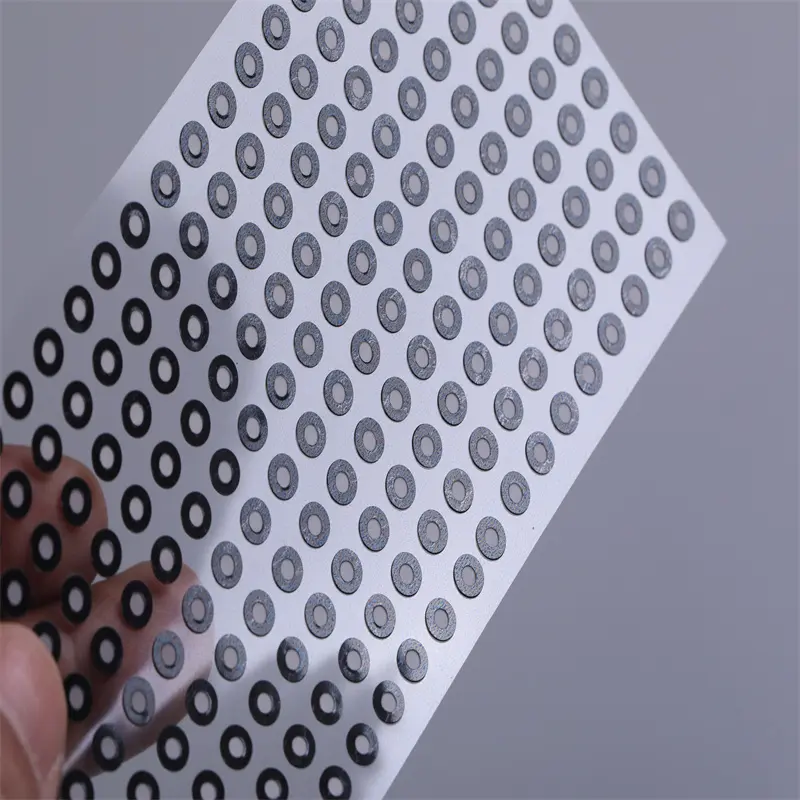

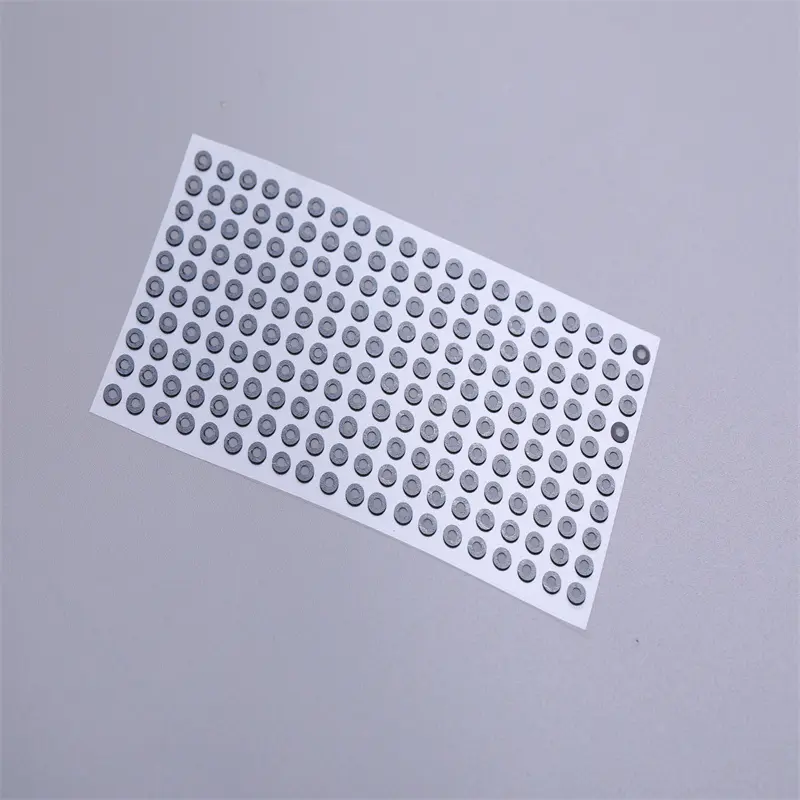

PRODUCT DIAGRAM : |

|

|

MEMBRANE MODEL : |

ZZPIP-E90H30 |

|

ADHESIVE MODEL : |

5610 |

|

PRODUCT DIMENSION : |

0.2±0.05mm; I4±0.2mm; 8±0.2mm; |

Product Properties

|

PHYSICAL PROPERTIES |

REFERED TEST STANDARD |

UNIT |

TYPICAL DATA |

|

Membrane Color |

/ |

/ |

White |

|

Membrane Construction |

/ |

/ |

PTFE / PET non-woven |

|

Membrane Surface Property |

/ |

/ |

Hydrophobic |

|

Thickness (Membrane & Adhesive) |

ASTM D374 |

mm |

0.2±0.05 |

|

Adhesive Strength |

ASTM D3330 (180° peel on SS Panel) |

N/inch |

16.9 |

|

Min Air Flow Rate |

ASTM D737 |

ml/min@ 7Kpa |

>1500 |

|

Typical Air Flow Rate |

ASTM D737 |

ml/min@ 7Kpa |

2300 |

|

Water Entry Pressure |

ASTM D751 |

KPa for 30 sec |

>10 |

|

IP Rating |

IEC 60529 |

/ |

IP68 |

|

Moisture Permeability |

ASTM E96 |

g/m²/24h |

>5000 |

|

Oleophobic Grade |

AATCC 118 |

Grade |

NA |

|

Operation Temperature |

IEC 60068-2-14 |

℃ |

-40℃~125℃ |

|

ROHS |

IEC 62321 |

/ |

Meet ROHS Requirements |

|

PFOA & PFOS |

US EPA 3550C & US EPA 8321B |

/ |

PFOA & PFOS Free |

Application

The membrane can balance inside/outside pressure differentials of sealed enclosures while blocking contaminants, which could increase components’ reliability and extend their service life.

Shelf Life:

Shelf life is two years from the date of receipt for this product as long as this product is stored in its original packaging in an environment below 80° F (27° C) and 60% RH.

Handling and Installation Guidelines

(Note:The following content is only applicable to manual installation plan, if you need to know automatic installation plan, please contact ZZPIP sales staff. )

Handling Guidelines

1) Operators should wear latex and powder-free gloves or fingercots when handling adhesive vents.

2) Avoid direct contact with the active venting area.

3) Keep all sharp or jagged items away from the ePTFE membrane.

Dispensing Guidelines

1) To prevent damage to the product, do not pry the diaphragm directly from the release film

2) For manual dispensing, roll the liner under the vent, slowly over an edge, until the vent extends beyond the liner and becomes accessible. Blunt-edged tweezers may be used to remove the vent gently from the liner.

Installation Guidelines

1. Preparation

a) Ensure that the enclosure’s mounting surfaces are smooth, clean and free from oils, particles or other contaminants; free from jagged or rough edges that could damage the vent.

b) Isopropyl alcohol can be used to clean the enclosure’s mounting surface.

c) Ensure that the enclosure’s mounting surface is dry prior to vent installation.

2. Positioning

a) The product should be mounted only on interior housing surfaces,ensuring the e-PTFE membrane side facing the external environment.

b) In order to achieve the best performance, the film should be installed on a flat, vertical surface to avoid liquid or other contaminants on the surface of the film.

3. Installation

a) Apply firm finger force at least twice in a circular motion directly to the adhesive ring area to seal the vent to the housing, being careful not to touch center of the vent area.

b) Ensure the entire adhesive ring is pressed against the surface.

c) Allow 24 hours cure time before using or testing.

4. Note

a) Once installed, vents should not be repositioned.

b) Vents will be damaged when they are removed from the mounting surface.

Note:

All data above are typical data for the membrane raw material, for reference only, and should not be used as special data for outgoing quality control.

All technical information and advice given here is based on Zzpip previous experiences and test results. Zzpip gives this information to the best of its knowledge, but assumes no legal responsibility. Customers are asked to check the suitability and usability in the specific application, since the performance of the product can only be judged when all necessary operating data are available.